So last time I had completed priming, and had masked off the SEAC white identification stripes.

The next task was to apply the camouflage colours of the Temperate Land Scheme—Medium Sea Grey undersides, and an RAF standard pattern of Dark Earth and Dark Green above. It’s always a puzzle how sharp-edged the camouflage patterns should be. Some patterns were reputedly applied using large paint masks, and so could be expected to be extremely sharp-edged at 1/48 scale. On the other hand, if camouflage was applied free-hand with a spray gun, one could expect to see softer edges, even at 1/48 scale. Looking at contemporary photographs wasn’t much help—some of the patterns on RAF Thunderbolts seemed to be very sharply defined, while others were very diffuse. So I decided I’d try for a softer edge by placing my masking a millimetre or so above the surface of the model, in an effort to simulate the effects of a free-hand spray job.

After painting the underside, I applied Dark Earth to the upper parts, and then laid on paper masks supported by thin rolls of Blu Tack. After an immense amount of fussing around getting the paper edges a reasonably uniform distance from the surface of the model, I sprayed on Dark Green. I had to keep reminding myself to keep the spray as much as possible at right angles to the edges of the masks—the last thing I wanted was to spray under the mask and get a thick line of pooled paint along the edge of the Blu Tack.

But this technique certainly removes a lot of the anxieties about paint leaking under the masking by capillary action. Except, of course, for my white SEAC stripes, with their closely applied masking tape—the white would show up any masking leaks all too noticeably. So there was the customary flicker of anxiety as I started to peel off all the layers of paper and Blu Tack and tape. But it worked out pretty well—a couple of tiny trickles along a couple of panel lines were swiftly removed using a little gentle pressure from a wooden cocktail stick, which didn’t disturb the underlying white paint. Then the whole thing was coated with gloss varnish, ready for the decals.

SEAC markings are surprisingly difficult to come by—those unobtrusive little Dull Blue and Light Blue roundels seem to be unpopular with model builders. I’ve previously had an unfortunate experience with a rather elderly set of SEAC decals, bought on eBay, which leaked some unpleasant gunk on to the paintwork while simultaneously refusing to bed down properly. But this time I was well served by Xtradecal’s sheet X48115—variously called “P-47D Thunderbolt in RAF/SEAC Service” or “Yanks with Roundels Part 4”. This not only gave me the roundels and flashes I needed, but as a bonus had the tail serial number for HB982, the aircraft immediately after mine in the RAF code sequence. With a “1” stolen from another set of codes, I was able to assemble the serial number I wanted using only two decals, rather than going through the usual performance of teasing five individual characters into alignment.

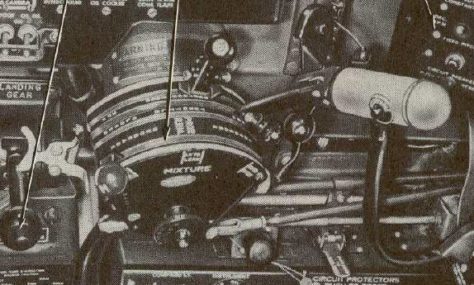

The WK-H squadron letters for this aircraft posed another. The official Temperate Land Scheme required code letters to be marked in Sky—a sort of duck-egg green shade. However, according to Geoff Thomas’s book, squadrons tended to mix their own paint from Dull Blue and White, “the resulting colours varying from Deep Sky to light grey-blue”. I’ve yet to find a colour photograph showing this, and looking at black and white photographs is of course no help at all. Here’s a 135 Squadron aircraft from a little earlier in the war:

© Imperial War Museum (CF 1242)

Are those code letters pale grey-blue or duck-egg green?

The problem was resolved for me, though not to my particular satisfaction, by how difficult it was to obtain RAF letters of the right size (18″) in any shade but Sky. Although pale blue letters are available for particular aircraft on the Xtradecal sheet, they didn’t match what I needed, and I couldn’t track down any white letters of the right size, which I could have tinted. A truly dedicated model maker would have produced his own stencils and sprayed the letters on, or printed them on to white decal backing and cut them out, and I actively considered those options for a while, before deciding that whatever I did, it would not be a match for the unknown original appearance. So I went with the standard Temperate Land Scheme—the letters I used are from Fantasy Printshop.

I added the various small stencils for fuel fillers and electrical connections supplied with the Tamiya decal sheet. I couldn’t find any photographs suggesting that a red “No Step” panel on the inboard flaps were used in RAF SEAC aircraft, so I replaced the panel provided on the Tamiya decal sheet with a plain stencil from my decal cache.

Once the decals had bedded in and dried thoroughly, I added another coat of gloss varnish and started marking up the (many, many) panel lines. As with previous kits, I used Lifecolor’s Liquid Pigment for this. It settles neatly into the engraved lines of the kit, and any excess can be removed (even when dry) with Lifecolor’s removal fluid. Careful wiping of partially removed pigment produces a nice preliminary weathering of the aircraft’s surface. The main trick to using this stuff is to keep shaking the bottle—it settles out very quickly, so the black liner will slowly turn blue if you don’t keep remixing the pigment.

Once that had dried, I applied a couple of coats of matt varnish, ready for final weathering and the addition of final bits and pieces like the undercarriage, propeller, guns and external fuel tanks.

And that’s where I’ll pick up next time.

or

I’m using the Tamiya kit to model a specific aircraft, again. This is going to be a Republic P-47D-22-RE Thunderbolt, on the complement of 135 Squadron RAF in Burma from April to May 1945. Its American serial number was 42-25818, with a British serial of HB981. It was what the RAF called a “Thunderbolt I”—what’s commonly referred to as a “razorback”, to distinguish it from the later “bubbletop” models, which the RAF designated the “Thunderbolt II”.

I’m using the Tamiya kit to model a specific aircraft, again. This is going to be a Republic P-47D-22-RE Thunderbolt, on the complement of 135 Squadron RAF in Burma from April to May 1945. Its American serial number was 42-25818, with a British serial of HB981. It was what the RAF called a “Thunderbolt I”—what’s commonly referred to as a “razorback”, to distinguish it from the later “bubbletop” models, which the RAF designated the “Thunderbolt II”.

And that was that. The Saturn V stack grows ever higher, but I’m going to take a break and do something else before I tackle the travesty that is Revell’s S-II stage.

And that was that. The Saturn V stack grows ever higher, but I’m going to take a break and do something else before I tackle the travesty that is Revell’s S-II stage.

This kit was first released fifty years ago. It’s a model of a real aircraft, the

This kit was first released fifty years ago. It’s a model of a real aircraft, the

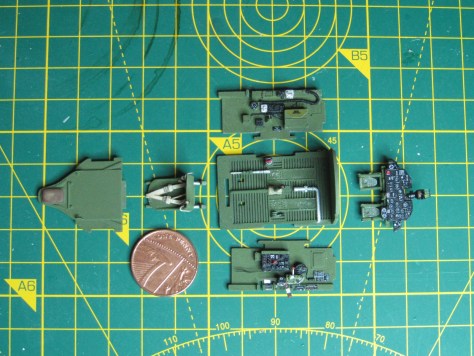

Now, I’m used to having a few pre-painted bits and pieces of a kit sitting in a pot waiting to be added to the overall assembly. What’s striking about this kit, though, (especially in the order I built it) is that it consists almost entirely of pre-painted bits and pieces. I had to get some bigger pots.

Now, I’m used to having a few pre-painted bits and pieces of a kit sitting in a pot waiting to be added to the overall assembly. What’s striking about this kit, though, (especially in the order I built it) is that it consists almost entirely of pre-painted bits and pieces. I had to get some bigger pots.

So this is my next project. I’m building another aircraft my father might have flown—a Hawker Hurricane IIB that was on the complement of No.71 Operational Training Unit, Ismailia, in the first few months of 1944.

So this is my next project. I’m building another aircraft my father might have flown—a Hawker Hurricane IIB that was on the complement of No.71 Operational Training Unit, Ismailia, in the first few months of 1944.

By way of a break from the slow building of my Saturn V, this one is an attempt to model one of the aircraft my father flew during the Second World War.

By way of a break from the slow building of my Saturn V, this one is an attempt to model one of the aircraft my father flew during the Second World War.